|

|

|

slot grabbing headaches

Tuesday, October 23 2007

fear not, explanatory photos follow!

The problem with an unfamiliar attachment technology such as the slots present on my new solar panel is that there's no simple way to definitively make an attachment using it. If it was a threaded hole, I'd get the correct bolt and screw it in, and that would be that. But now I've been forced to bend bits of commodity steel into novel shapes without the certainty that the tabs I'm sliding into those shallow slots will really hold. Today I was so anxious imagining lifting the panel in its present condition that I decided to upgrade my attachments by including tabs that go into not just one but both of the circumferential slots in the solar panel's frame. This required me to make a second, simpler piece of bent metal which I laminated between the existing slot grabber and the backing girder. But because these sets of slot grabbers were only being held by a single bolt each, the extra lamination destablilized the whole system, causing it to slosh around a bit when I applied test forces. That wasn't good.

So I tried what I thought might be the simple way out, welding the slot-grabbing assemblages to the backing girder. And though I have a gas-welding kit, I've never successfully welded anything. So there I was with my goofy welding mask on, attempting to get metal to fuse together under a bright blue flame fueled mostly by pure oxygen. I don't know if it's my cheapo kit that's the problem of if I just don't know what I'm doing, but I couldn't get anything to happen, and I ran out of canned oxygen before I could do much anyway.

So then I bought another bottle of oxygen and more bar steel at Herzog's hardware in Uptown and set my sights on a smaller goal, simply to weld a second steel tab onto the larger of the two slot-grabbing pieces. I worked at this for a frustrating half hour or so, managing to melt one of the steel bars into a glowing droplet of molten steel which looked like it had fused with what I was trying to weld it to. But then when I turned off the oxygen and let the joint cool, it was clear the two pieces of metal had never been fused. It had been a complete waste of oxygen (which, paradoxically, is the most expensive commodity one uses in gas welding). I really need to get myself an arc welder and put my pathetic gas welder to bed.

In the end I completely redid all four of my slot-grabbing contraptions. For the two corners that will be most-stressed by lifting, I made contraptions that grabbed both slots and were secured by two screws each, keeping the connections immobile. For the two least-stressed corners, I built contraptions that only grabbed one slot but were still secured by two screws each. After I was done installing these, I felt confident that they would support the panel both during the installation lift and later after it is screwed down to the solar deck annex.

The set of old frame slot grabbers from earlier today. That thing at the bottom is the piece of steel with the glob I melted in my failed welding attempt. They look like steel Hebrew letters, but aren't like any that actually exist.

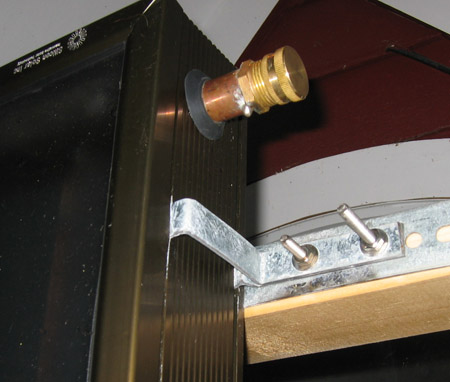

A final upper frame slot grabber, on the solar panel and secured to the backing girder.

Note the lathed fitting soldered in place, capped with a conventional hose cap. When I soldered the fitting there, I'd wrapped that nearby rubber gasket with wet paper to keep it from melting.

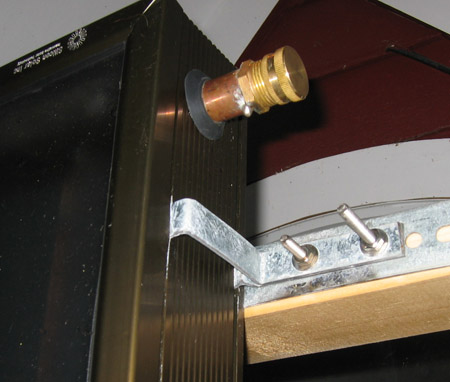

A final lower frame slot grabber, on the solar panel and secured to the backing girder.

For linking purposes this article's URL is:

http://asecular.com/blog.php?071023 feedback

previous | next |