|

|

|

rail dolly hoist

Sunday, September 28 2014

Today I installed a small amount of mounting hardware in the greenhouse to support a 160 inch two by six rail running a couple inches beneath the downstairs ceiling from west to east about 46 inches from the north wall. On the west end, the rail could be supported by a ledge where glass blocks (which are thinner than the concrete blocks that make up the walls) form a small window at the top of the wall. On the east end, though, there was no such ledge, so I screwed a joist hanger into the wall, though I installed it upside down so the rail could be slid into it from below and then held in place by multiple screws. This would allow me to easily remove the rail to gain access to, remove, and maintain the dolly (as there is not enough headroom to remove the dolly without dropping the rail). To help keep the rail oriented with the 5.5 inch dimension of its cross-section oriented vertically, I also attached a joist hanger to the west concrete wall just beneath the ledge where the glass block windows sit using an unsatisfying mix of screws and epoxy. (I found it impossible to drill holes any deeper than 3/4 inch into the wall.)

Forgetting that it was Sunday, I went into town with the ultimate plan of swinging by Barnyard Feeds on Route 28 on my way back home. First, though, I drove out to 9W to buy some things at Lowes, Home Depot, and ShopRite. If you're an IPA lover on the East Coast, one of the cheapest excellent beers you can buy is Sierra Nevada Torpedo, and, though they sell it at ShopRite, it's a real indication of the demographic that shops there that whenever I buy SNT there, the six pack is always extremely dusty. (This is less true of Little Sumpin' Sumpin' Ale and never true of the macrobrews.) The main hardware purchases were 13 inch pieces of threaded rod, one a half inch thick and the other 5/8 inches thick, each with washers and nuts to go along with it. I would have bought just one, but once in Lowes, I couldn't remember if the strap of steel on the dolly had half inch or 5/8 inch holes for the horizontal rod that will ultimately support the top pulleys of the block & tackle system.

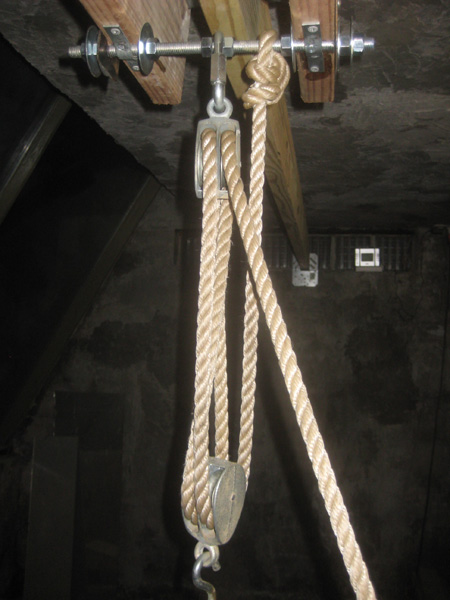

Back home, it turned out that the rod I needed was the half inch one. Once I had the dolly put together and the long two by six cut to size, I installed the hoist system and threaded fifty feet of rope through the two pulley blocks (each of which contain two pulleys). I then jackhammered away at the bottom of the excavation so as to produce some rocky rubble to remove and then lifted it out with the hoist. It worked well on the first attempt, and I was pleased to find that the dolly moved easily even when fully loaded (but not so easily that I couldn't park it in some particular place along the rail). The problem came when I went to lower the emptied bucked back down in the excavation; at that point the rope became all twisted and I had to untangle the mess before proceeding. Obviously, that wasn't workable. I'd encountered this in the past with my kayak hoist and perhaps even the solar panel hoist (though I'd only needed to use that for a single vertical lift). Researching the matter, I discovered that it all comes down to how the pulleys are threaded and the twisting pattern used to produce the rope. No general theory was spelled out and no particular solution was advanced, so I was forced to experiment. After several tries, I finally produced a rope-threading pattern that worked (see the photo below).

The rail dolly for the new hoist system. (Click to enlarge.)

After much trial and error, this was the block & tackle threading pattern that did not tangle.

For linking purposes this article's URL is:

http://asecular.com/blog.php?140928 feedback

previous | next |