|

|

|

hinged section of dock floated

Saturday, June 25 2022

location: 800 feet west of Woodworth Lake, Fulton County, NY

This morning I got up early and drove down to the public dock to drop off the repaired floater I'd picked up yesterday evening from Kadco. I found the lake glorious placcid and mirror-like, and there were a couple beavers, one of which was tiny and the other of which slapped her tail in aggravation.

Back at the cabin, I made myself coffee and ate a few tofu-and-kimchi sandwiches while waiting for the sun to rise high enough for me to turn on the refrigerator and the hot water heater (both of which I'd turned off last night after dipping a little too far into the cabin's battery). But the cabin is arranged in such a way that it collects more sun in the later part of the day and less in the earlier part. So I ended up passing the time by playing the New York Times Spelling Bee and collecting yet more clumps of plants to help control erosion back behind the cabin. (These efforts are now largely working; despite recent heavy rains, there hasn't been much more erosion.)

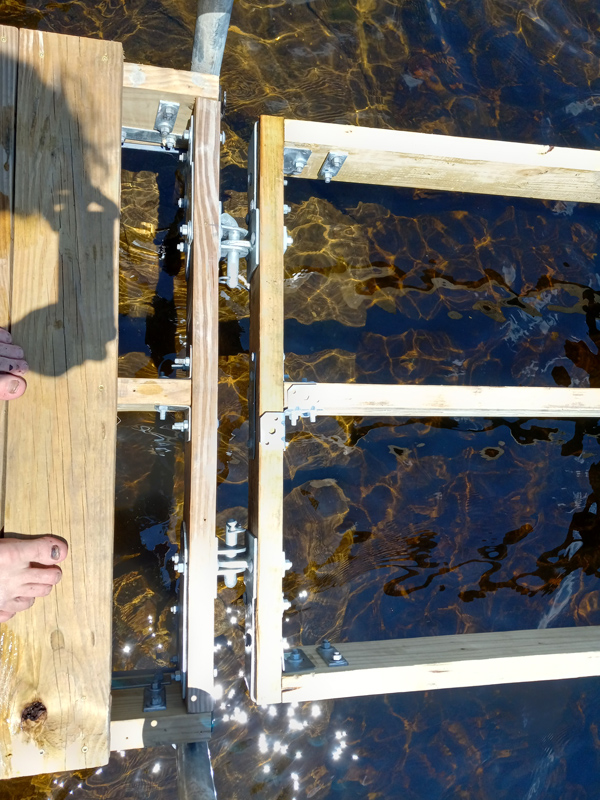

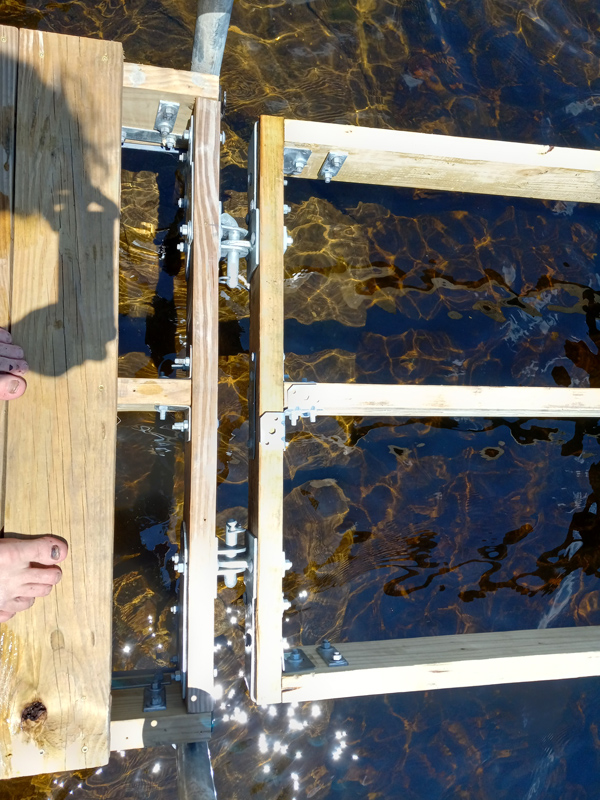

When I finally could turn on the refrigerator and walk down to the lake, I gathered up the power tools I needed and made myself a travel mug of kratom tea. The first task at the lake was to canoe over to the public dock to pick up the floater (and some metal brackets) I'd staged over there. Once I'd done that, I began redoing the corner brackets of the hinged section of dock on the end where it would connect (via hinges) to the existing stationary dock. I wanted the hinge pieces to be attached extremely solidly, and it was also important that the corners be very strong as well. It had occurred to me that if a floating dock at the end of a hinged dock is exposed to any currents, those forces will be greatly amplified at any hinge via the effect of leverage. What I'm adding to the fixed dock is 18-to-20-foot lever, so I have to be certain that the structure of the hinge (and associated material) is as solid as I can possibly make it. Fortunately, I had some very thick metal corner brackets leftover from the Kadco kit (originally intended for just the floating section of dock). I also had a couple wimpier corner brackets I'd just bought on eBay to use for beefing up the upper parts of the end corners of the fixed part of the dock, a structure whose joists are two-by-eights that had only been fully-bracketed at the bottom (at their attachment to the pipe-piers the dock rests on). In doing all this, I found a use for some large thick plates, though I had to slightly modify these by drilling additional holes. My Ryobi impact driver (and heavily-used 3/8 inch bit) didn't much like these drilling tasks, but the grudgingly carried them out all the same. I've been using a small stump as solid surface for drilling objects against, and it was soon covered with spiralling metallic swarf, some of it an inch or more long and blue from extreme heat resulting from all the friction.

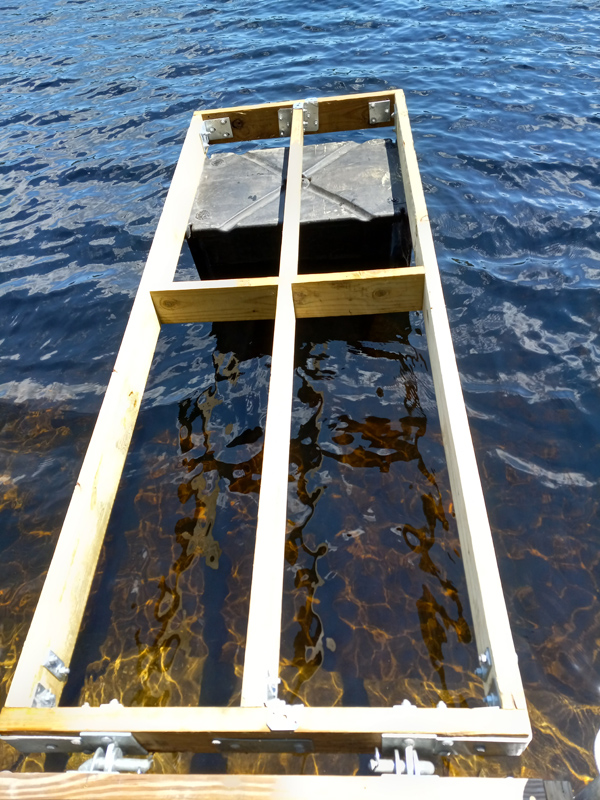

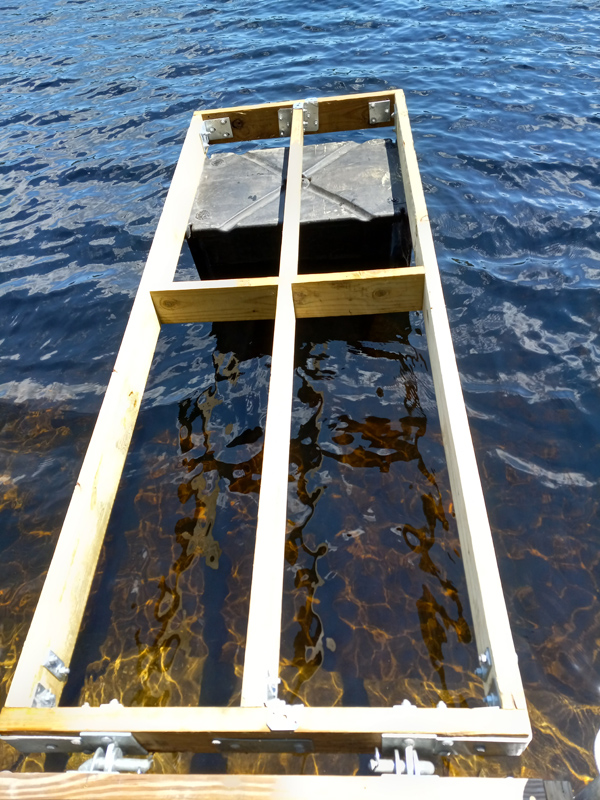

Once I had all this new solid hardware in place, I could bolt the new floater to the bottom of the end of the hinged section of dock (only four four-inch-by-3/8-inch lag bolts), push the whole thing off out into the water, and attach the hinge pins. The new half-floating section of dock seemed to function as desired, easily supporting my weight when I climbed out onto its end (something I had to do carefully, as there wasn't yet any decking). I should mention that even just this little section of dock framing (featuring three eight-foot two-by-sixes, a 33-inch two-by-six cross-member, and lots of steel hardware) was very difficult and awkward for me to move; I'm now dreading the prospect of moving the big ten-by-twelve-foot framework for the fully-floating section of dock.

Since the next task (installing decking on the hinged section of dock) would require a saw, I returned to the cabin, ate a quick semi-nutritious lunch, checked my usual internet destinations, and then gathered up my tools for my next stint at the dock.

As I approached the dock, I could hear something of a party happening down at the lake. Someone was blaring country music from an audio system, and I would soon see a few people hanging out on inflateable structures deployed for relaxing summer Saturdays. I was little slow in getting to the lake myself, because I was using a battery-powered chainsaw to clear a new diagonal section of trail to shorten the walking distance to the lake while also eliminating a section of steep grade. The original trail, you see, first goes straight to lake 200 feet or so north of the dock, and then one must walk along the lakeshore to get to the dock. My new section of trail angles down toward the dock and down the slope more gradually, though the terrain it traverses is still far from ideal, containing a number of humps and troughs that ideally would be smoothed out somehow.

While I was out on the end of the new section of dock with an impact driver, screwing down forty inch two-by-six deck planks, a couple fishermen in kayaks paddled past. One of them made smalltalk, which is what one expects in such a situation. "Is it coming along?" he asked, regarding the dock. I said it was, but then of course felt the need to add something a bit beyond the usual smalltalk. "The forces on these things is such that they really have to be built strong," I said. "Uh huh," said the fisherman. And then he and his friend were gone, which was all either of us wanted.

Once I had nearly all the decking in place. I walked around on it and was surprised by how solid it felt. If anything, it was riding a little high on the water, and I wondered if this would distort the orientation of the main rectangle of floating dock. I measured the depth of the water off the end of the new section of dock and it was 81 inches, which is considerably deeper than the 18 inches of water (at best) off the end of the fixed section of dock. That the lake bottom falls away 63 inches in only 96 inches of horizontal distance gives you a sense of how steeply it slopes.

Another thing I did this afternoon at the dock was to remove the last two joint-hangers foolishly installed on the framework for the floating dock section. I had a couple proper angle brackets I could replace them with. They weren't as solid as the other angle brackets, but I had a felling that I'd over-built most of it.

When I was done with my dock chores, I paddled over to the outlet bay and gathered more pieces of stone for the dock's abutment.

Throughout the day as I worked, there was a loon (Gretchen and I have myth that this is Throckmorton, the loon from Twenty Ninth Pond) visible on the lake, often not far away. The loon was never much disturbed by my construction noises (banging in carriage bolts, firing the impact wrench, and power-sawing two-by-sixes), and at one point surfaced only about thirty feet away (I could've taken a good picture with just my cellphone had I had it handy). Throckmorton didn't make much noise; I think he warble-whooped only once the whole day, and that was in the morning.

Back at the cabin, I cup up several large mushrooms and used them to fully-cover a vegan pizza having faux pepperoni. Such pizzas aren't much food when split between two people, but when eaten by one (even someone who has worked hard all day) it's a genuine feast.

All the hardware that goes into attaching the fixed dock section (left) with the hinged section (right). Click to enlarge.

The hinged section with its floater, floating.

The hinged section as part of the overall dock, which is now 24 feet long.

Click to enlarge.

For linking purposes this article's URL is:

http://asecular.com/blog.php?220625 feedback

previous | next |